Manufacturing Services

Manufacturing & Global Souring

- Any kinds of plastic and metal product manufacturing

- Low cost global sourcing from Asia

Email: [email protected]

Phone: 1-240-421-0756

Fax: 1-866-304-9034

Address: 15720 Brixham Hill Ave. Suite 300, Charlotte, NC USA 28277

Our Global Sourcing and Manufacturing Services

At FEAmax LLC, we specialize in providing comprehensive engineering manufacturing and global sourcing services, ensuring your products are created with the highest quality standards. Our manufacturing sourcing services are designed to connect you with the best global suppliers, ensuring cost-effective and efficient production processes. With over 20 years of experience, we excel in both metal and plastic manufacturing, catering to diverse industry needs.

Our global sourcing capabilities enable us to find the most reliable and skilled manufacturers worldwide, guaranteeing that your projects are completed on time and within budget. We offer end-to-end engineering manufacturing services, from initial design and prototyping to full-scale production. Our expertise in metal and plastic manufacturing ensures that every component meets stringent quality requirements, providing you with durable and high-performing products.

Partnering with FEAmax LLC means benefiting from our extensive network of global sourcing partners and our commitment to excellence in engineering manufacturing. Contact us today to learn how our manufacturing sourcing services can enhance your production capabilities. Discover the difference that professional engineering manufacturing services and strategic global sourcing can make for your business.

Our Mission:

- Since 2005, we have been at the forefront of offering cost-effective engineering design, analysis, manufacturing and global sourcing services.

- Our enduring alliances with over 25 esteemed product manufacturers and material suppliers across Asia (including China, Vietnam, India) and the US, enable us to present highly competitive quotes for both metal and plastic products.

- Our seasoned manufacturing engineers stand ready to guide you in material selection, design optimization, and tooling issue prevention, all while ensuring the production of superior quality products. We are committed to delivering the finest quality and cost-efficient solutions, tailored to give our customers a distinctive edge in the marketplace.

- We navigate the complexities of international sourcing, ensuring quality control, supply chain reliability, and compliance with industry standards. Our experienced team manages the end-to-end process, from selecting vetted factories to overseeing production and logistics. Partner with us to leverage the strategic benefits of Asian manufacturing, enhancing your product's journey from concept to market with expertise and precision.

Our manufacturing and outsourcing services:

- 3D scanning and 3D printing prototyping.

- Mold Making: injection mold, blow mold, gas assist mold, etc.

- Die Casting and CNC.

- Make any metal and plastic products.

- Global Outsourcing from Asia and the US.

- etc.

Our Engineering Services

Area Of Expertise

Introduction of our Services

- We started our business in 2005. At FEAmax LLC, we’ve crafted a robust platform for Manufacturing and Global Sourcing that combines expertise, efficiency, and a deep understanding of the global market. Since our inception, we’ve established and nurtured strategic partnerships with over 25 top-tier manufacturers and material suppliers across Asia—including powerhouses like China, Vietnam, and India—and the United States.

- Our strength lies in delivering not just products, but comprehensive solutions that encompass the entire manufacturing process. From providing competitive quotes for metal and plastic products to navigating the intricate web of global supply chains with ease, we specialize in transforming challenges into opportunities. Our team of adept manufacturing engineers works closely with clients to meticulously select materials, refine designs, prevent tooling issues, and ensure the end product stands up to the highest quality standards.

- We are committed to upholding a tradition of excellence, offering our customers the highest quality services while ensuring cost-effectiveness. Partner with us to leverage the potent mix of local insight and global reach, all designed to empower your business.

- Supplier Identification: Finding and qualifying potential suppliers worldwide based on product quality, production capacity, and cost-effectiveness.

- Procurement: The actual purchasing of goods and services from global suppliers, including negotiation of contracts and terms.

- Logistics and Supply Chain Management: Managing the transportation, warehousing, and delivery of goods across international borders, dealing with customs, import/export regulations, and shipment tracking.

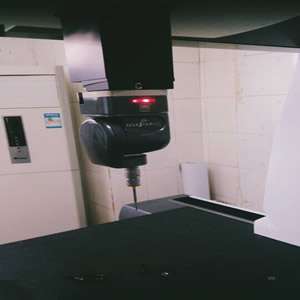

- Quality Control: Ensuring that the products sourced meet the required standards and specifications, which may involve on-site audits and continuous quality assurance processes.

- Cost Management: Keeping track of the total cost of sourcing, including product costs, shipping, duties, and any other fees associated with importing goods.

- Risk Management: Identifying, assessing, and mitigating risks associated with global sourcing, such as political instability, currency fluctuations, or supply chain disruptions.

- Legal and Regulatory Compliance: Understanding and adhering to the legal and regulatory requirements of different countries, including labor laws, environmental regulations, and safety standards.

- Market Analysis: Staying informed about global market trends, exchange rates, and the economic conditions of supplier countries.

- Ethical Sourcing: Ensuring suppliers adhere to ethical practices in terms of labor, sustainability, and corporate social responsibility.

- Strategic Sourcing: Aligning sourcing strategies with overall business goals to create a competitive advantage, which can include developing long-term relationships with suppliers or investing in supplier development.

- Our OEM (Original Equipment Manufacturer) services are designed to bring your product concepts to fruition with precision and efficiency. We specialize in manufacturing high-quality products under your brand name, tailored to meet your specifications. With our expertise, we handle everything from product design, engineering, and prototyping to final assembly and quality control. Our commitment to excellence ensures that we use only the best materials and the latest manufacturing technologies to deliver products that stand out in the market.

- We collaborate closely with our clients to understand their unique needs, ensuring that every aspect of the product reflects their vision and brand identity. Our streamlined production processes and rigorous testing protocols guarantee that each item we manufacture meets the highest standards of quality and performance. By choosing our OEM services, you gain a reliable partner who is dedicated to delivering exceptional value and competitive advantage, allowing you to focus on growing your business.

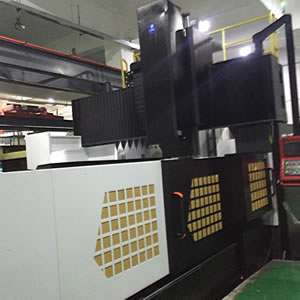

- Our Computer-Aided Manufacturing (CAM) service represents the pinnacle of technological integration in the manufacturing process. We provide sophisticated solutions that convert computer-aided design (CAD) outputs into executable machine instructions, facilitating the creation of complex parts and assemblies with precision and speed. Our CAM capabilities span a wide range of manufacturing operations, including CNC machining, laser cutting, punching, and more.

- We pride ourselves on the efficiency and accuracy our CAM services bring to the production floor, optimizing tool paths to reduce waste and enhance productivity. With our advanced software and state-of-the-art equipment, we can ensure that every product is manufactured to the highest quality standards. Our team of experts works seamlessly with your designs, providing a streamlined transition from digital blueprints to tangible, high-quality products. Choose our CAM services to capitalize on the benefits of digital manufacturing, minimizing lead times and maximizing your project’s success.

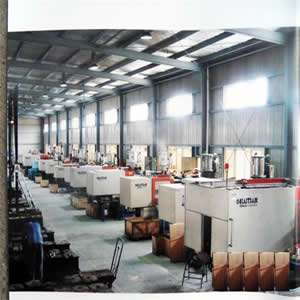

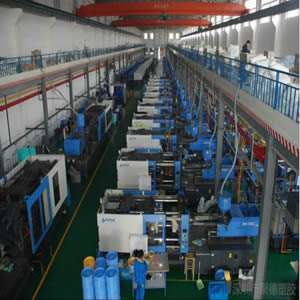

Manufacturing Equipment from our Partners

- Precise E.D.M

- Numerical Control Lathe

- Milling Machines

- Precise Wire Cutting

- Spotting Machine

- Hot Runner System

- CNC Machines

- Grinding Machine

- Gas-Assisted Injection

- Hydraulic Cylinder

- Deep Drilling Machine

- Etc.