FEA Consulting Service

Finite Element Analysis (FEA)

- All types of structure stress analysis

- Engineering design and optimization

Email: [email protected]

Phone: 1-240-421-0756

Fax: 1-866-304-9034

Address: 15720 Brixham Hill Ave. Suite 300, Charlotte, NC USA 28277

Our FEA Consulting Services

At FEAmax LLC, we specialize in providing top-tier Finite Element Analysis (FEA) simulation services tailored to meet your specific needs. Our team of experienced Finite Element Analysis consultants utilizes advanced FEA techniques to deliver precise solutions for complex engineering challenges. With over 20 years of experience, we ensure that your designs are optimized for performance, safety, and cost-effectiveness.

Our FEA simulation services cover a wide range of industries, including aerospace, automotive, manufacturing, and civil engineering. Whether you need stress analysis, thermal analysis, or dynamic analysis, our Finite Element Analysis consultants are equipped to provide detailed insights and actionable recommendations. We use state-of-the-art simulation tools to model and analyze the behavior of materials and structures under various conditions, ensuring that your projects meet the highest standards of quality and reliability.

Partner with FEAmax LLC to benefit from our extensive expertise and commitment to excellence. Contact us today to learn more about how our FEA simulation services can elevate your engineering projects. Discover the difference that expert Finite Element Analysis consultants can make for your business.

What is FEA?

- Finite Element Analysis (FEA) is a numerical simulation (computerized) method for predicting structure response to real-world load or testing conditions.

- The FEA simulation could find out potential design issues, allow for design/process changes in very early stage, and then save project redesign/testing time, cost, etc.

Our Mission:

- Provide low-cost professional FEA consulting services in various industry fields, specializing nonlinear, dynamic, vibration, thermal, drop test, fatigue and stress analysis.

- Evaluate the structure performance and provide suggestions to improve and optimize the design.

What we need to determine the quote and run FEA simulation:

- 3D CAD model, or 2D drawings with all dimension information.

- The detailed load condition.

- Material property for each component.

- What are your main concerns from the analysis.

What we provide on FEA project:

- A full standard FEA analysis report including results, conclusion, comments and suggestions.

- The FEA results include: stress, strain, deflection, safety factor, reaction force, temperature, etc.

- Find out potential design issues and provide suggestions to optimize or improve the design.

- Colorful images and animation files.

- Q & A

Our Engineering Services

Area Of Expertise

Static Analysis

- Static Linear Stress Analysis

- Geometric Nonlinear Analysis

- Material Nonlinear Analysis (creep, plasticity, hyper-elasticity, etc.)

- Contact Nonlinear Analysis (frictional contact)

Dynamic Analysis

- Seismic/Vibration Analysis

- Modal Analysis

- Harmonic Analysis

- Spectrum Analysis

- Transient Impact Analysis

- Fracture Analysis

Thermal Analysis

- Steady Thermal Analysis

- Transient Thermal Analysis

- Conduction Analysis

- Convection Analysis

- Radiation Analysis

- Phase Change Analysis

Other Analysis

- Fatigue Stress Analysis

- Buckling Analysis

- Electromagnetics Analysis

- Composite Analysis

- Acoustic Analysis

- Multiphysics Analysis

Introduction of FEA

The Finite Element Method (FEM) is fundamentally a numerical technique. Predominantly, it refers to the complex mathematical procedures used in an analysis solver. This method is strategically used to perform Finite Element Analysis (FEA) under any given load condition.

The Finite Element Method (FEM) is numerical technique extensively employed to perform Finite Element Analysis (FEA) of any given physical phenomenon.

FEA is extensively and widely utilized in numerous industry fields. These include, but are not limited to, mechanical, aerospace, automotive, construction, oil & gas, electronics, heavy equipment, sports, and bio-mechanics, among others. More specifically, it holds pivotal importance for the purpose of designing machines, subsequently analyzing the fatigue life for the parts, and even evaluating the load capacities for lifting cranes. Furthermore, it plays a crucial role in constructing bridges and, quite significantly, in determining the crash/impact performance of vehicles, etc.

- FEA could test real world conditions on the design, predict the stress, deflection, safety factor, temperature, buckling deformation, fatigue, resonance frequency, fracture, etc.

- Find out and solve potential design issues at the very early stage, save material, time and cost.

- Evaluate the structure performance, find out the design defects before prototype, and provide design direction for design/product engineers.

- Optimize the product structure to achieve the best performance.

- Enhance design and provide better insight into critical design parameters. Contribute to faster and less expensive design cycle.

- It is the best choice for the cases which can’t be done by the real lab test.

- Static Structure Analysis: linear/nonlinear stress analysis

- Dynamic Analysis: transient, impact, drop test.

- Vibration/Seismic Analysis: modal, harmonic, spectrum.

- Thermal Analysis: steady, transient, conduction, convection, radiation.

- Fatigue Analysis.

- Linear/Nonlinear Buckling Analysis.

- Electromagnetics Analysis.

- Fracture Analysis.

- Composite Analysis.

- FEA is numerical simulation tool and it is approximate method: the analysis is performed on a virtual CAD model. All the results are approximated and the user cannot precisely estimate and compare the difference between the obtained results and the real ones.

- The simplified model, material data, load condition, stress concentration and other factors may cause inaccurate analysis results.

- FEA can be computationally expensive if have complex problem, and the cost of professional FEA software is high.

- FEA is hard to learn and use: a short-term training could be good to use FEA to solve simple analysis project. But the professional FEA software could be very complex with many options and capabilities. To be expert in FEA, we need many years of learning and practicing.

- To work on complicated FEA project, we may need to have: FEA expert with experience and knowledge, professional FEA software, high performance computer, etc.

- To obtain accurate and reliable analysis result, we should have much experience and knowledge on FEA and use the professional FEA analysis software:

- Stress concentration or singularity: it could be caused from specific areas of analysis model or the load condition, such as: sharp corner of model or concentrated point load. We need to be very careful to check and verify the analysis result of maximum stress. Manual judgement is essential in the analysis and post process.

- Model simplification: the simplified model should not affect the accuracy of the result on the main concerned areas.

- Material data: the simplified linear material data might result in inaccurate analysis result. We may need to choose the specific nonlinear material data for the analysis project, such as: bi-linear isotropic hardening model, hyper-elastic material data, visco-elastic material data, etc.

- Load condition: the load condition should be reliable, the same or very close to the real world test condition. We should be very careful to simplify the load and boundary condition.

- Meshing: the mesh density, number and type would affect the analysis result.

- Contact condition: we need to choose the correct linear or nonlinear contact type in the analysis program.

- Analysis type and solver: the nonlinear (geometry, material and contact) analysis would obtain the more accurate analysis results but the running time would be much longer.

-

The top suppliers of Finite Element Analysis (FEA) software are: Autodesk, ANSYS, Dassault, MSC, COMSOL, ESI, Simscale, Altair, etc. The most popular FEA software includes:

- ANSYS: the professional and most widely used FEA software in industry field. It is a complete package with structural, electromagnetic and Flow Simulation. Also, ANSYS has its pre processor, solver and post processor in single package. The Ansys Workbench makes it easier to make more informed design choices by coordinating all your simulation data in one place.

- ABAQUS: it has a very intuitive GUI interface, is quite powerful and widely used in research institutes and industry fields. Abaqus does a good job of handling contact, plasticity, and other non-linear problems. It also has the ability to incorporate Python scripting into a model, which gives the user a lot of flexibility in their analysis. The Abaqus product suite consists of five core software products: Abaqus/CAE, Abaqus/Standard, Abaqus/Explicit, Abaqus/CFD and Abaqus/Electromagnetic.

- COMSOL Multiphysics: it is renowned for its connectivity with other software such as MATLAB™, Java™, and Autodesk™ Inventor. And it provides lots of kinds of analyses tools such as electrical applications, fluid, mechanical analyses such as static and dynamic systems, chemical analyses, and acoustics.

- MSC Nastran / Patran: it was created by NASA and has various kinds of linear, non-linear, steady-state, transient analysis tools ranging from mechanical tools to fluid tools. Nastran is a solver with capabilities of Structural and vibration analysis. But, pre and post processor is required for Nastran. It is typically used for solving dynamic problems, powerful for beams and 2D analysis, strong analysis capability in aerospace field.

- SimScale: It is also an alternative to ANSYS finite element analysis software. SimScale is cloud-based computer-aided finite element analysis software that includes 3 main tools: thermal analyses, CFD analysis, and general mechanical analyses. Using this type of software allows for accurate calculations to be done without the need for esoteric calculations involving tensors, matrices, and integrals.

- OpenFoam: The OpenFoam finite element analysis software is an open-sourced software program. It is completely free CFD (computational fluid dynamics) software that academics and students can use. The main goal of OpenFOAM is to provide a cost-effective and scientifically accurate solution to the design, testing and fabrication of mechanical and electronic systems that maximize performance. It is designed specifically to meet the challenges facing the oil and gas industry.

- LS-DYNA: LS-DYNA is an advanced general-purpose multi-physics simulation software package developed by the former Livermore Software Technology Corporation, which was acquired by ANSYS in 2019. LS-DYNA is a very advanced FEA tool for non-linear and large deformation analyses. It is powerful for the explicit dynamic analysis (transient, impact, drop test). It is used by the automobile, aerospace, construction, military, manufacturing, and bioengineering industries.

- AutoDesk CFD: Autodesk provides a CFD module that users can simulate their fluid systems on a finite element analysis basis. Important feature of Autodesk CFD is the ability for users to plug it into existing designs or projects and automatically adjust any input parameters without having to know anything about the design or project itself.

- Hypermesh: Altair HyperWorks™ is a computer-aided engineering software provided by Altair Engineering Inc. Hypermesh provides tools to create effective meshes for multiphysics applications. It is dedicated to meshing and it is only used for pre-processing. The big strength of Hypermesh is that it enables the user to define own meshes and define them for specific purposes. The Hypermesh is the most powerful meshing tool, it could generate meshes on CAD model and then use other FEA solver to run the analysis.

- FEA Modulus in CAD software: Many CAD software has the FEA modulus and has the capability to run the FEA simulation, such as: Solidworks Simulation, Creo Simulation, Inventor Nastran, etc. These FEA modulus are good to solve simple and medium complex FEA problems. For complicated FEA projects, the professional FEA tools are still the best choice.

- Other FEA software: There are some other FEA analysis tools including: SAMCEF, ADINA, IVRESS, COSMOS, etc.

-

- Step 1 – Pre-processing: Create CAD model, simplify and input the analysis model into FEA program, assign the material data.

- Step 2 – Choose the correct connection type for each pair of contacts.

- Step 3 – Meshing the model: choose the correct mesh type and density on main concerned areas.

- Step 4 – Choose the correct analysis type and solver: static/dynamic, linear/nonlinear, etc.

- Step 5 – Apply load and boundary condition: make sure the load condition is the same as the real load and always consider the worst case.

- Step 6 – Run the analysis.

- Step 7 – Review and verify the analysis results.

- Step 8 – Prepare the formal FEA report including job description, parameter settings, results, conclusion, comment, suggestion, etc.

- Take some classes of FEA theory, understood the general concepts of structure mechanics and materials.

- Take about one or two weeks training class of the FEA analysis software.

- Start with simple problems.

- Practice, learn from instructors and peers.

- The simple FEA is helpful for engineers to understand insight and address the design issues quickly.

- Start with the educational background in particular mathematics, mechanics, physics and materials.

- Solid understanding of the related mathematics, including linear and tensor algebra, differential and integral calculus, etc.

- Take classes of FEA theory in different application fields, fully understand the theory on the FEA program.

- Take training class of the FEA software on different analysis types.

- Don’t just learn the software, learn the theory and modeling techniques.

- Start with simple problems, and do much practice, learn from instructors and peers.

- Correlate the FEA result to the physical testing results, get experience for future better analysis on similar projects.

- Be patient, it takes time and practice to be a specialist.

FEA Project Showcase

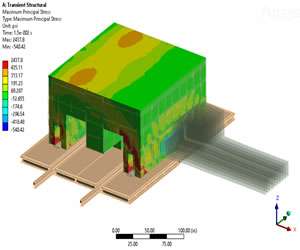

Seismic Stress Analysis

Performed a modal and vibration stress assessment on a pipe cage model affixed to a level surface, simulating a seismic event corresponding to a seismic zone 4 area. The objective was to determine regions of high stress concentration when the piping stood independently, without any connection to other CDU modules. The Finite Element Analysis (FEA) was used to predict the structural response under the load of the earthquake spectrum, identify weak points, and evaluate overall structural performance.

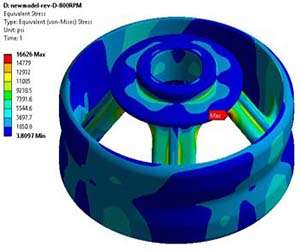

Fatigue Stress Analysis

Conducted a static structure stress analysis on the wheel model using Finite Element Analysis (FEA), predicting key parameters such as maximum stress, deflection, minimum safety factor, and reaction force. As the component undergoes cyclic loading during operations, a fatigue life assessment was also performed. Utilizing the material’s S-N curve in a fatigue stress analysis allowed us to estimate the product’s fatigue life, anticipate potential fatigue failure areas, and subsequently suggest design modifications to enhance the product.

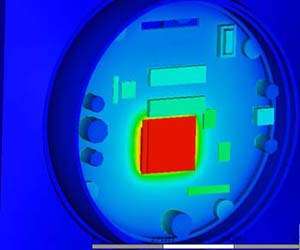

Thermal Analysis

The heat source within a micro-chip structure can produce transient high temperatures, leading to significant thermal deformation and stress. We executed a Finite Element Analysis (FEA) transient thermal stress assessment on this micro-chip structure, determining the temperature, deflection, and stress distribution at various time instances. FEA thermal analysis is typically employed when the primary objective is to evaluate temperature distribution, thermal stress, or when the boundary conditions are clearly established.

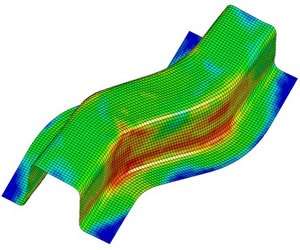

Metal Forming Analysis

FEAmax offers a comprehensive suite of metal forming simulations that encompass a wide range of processes such as die casting, stamping, hydraulic pressure, tube bending, and heat processing, among others. Our specialized, on-demand forming simulation services are designed to enable you to virtually test and validate your metal tooling designs. By using these virtual simulations, you can significantly reduce the risk of real-world failures, thus saving invaluable time and resources. This unique approach not only enhances efficiency but also facilitates a more cost-effective and reliable design and production process.

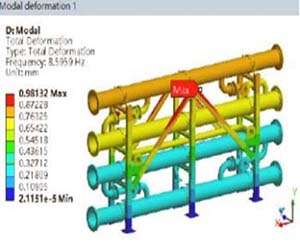

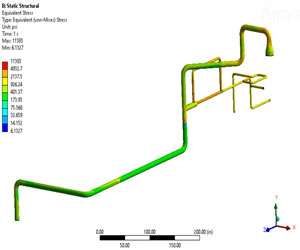

Piping Stress Analysis

Finite Element Analysis (FEA) is a powerful tool used for pipe structure stress analysis. This technique helps engineers understand how a piping system responds to various factors such as material properties, pressure, temperature, and fluid flow. The piping structure analysis provides insight into the overall system behavior. FEA aids in predicting the areas of high stress concentration, potential deformation, and possible failure points in the piping system. This information is crucial for ensuring system reliability, enhancing safety, and improving the design process. With FEA pipe structure stress analysis, engineers can make informed decisions.