CFD Consulting Services

Computational Fluid Dynamic (CFD)

- Analyze all problems involving fluid flows

- Fluid structure design and optimization

Email: [email protected]

Phone: 1-240-421-0756

Fax: 1-866-304-9034

Address: 15720 Brixham Hill Ave. Suite 300, Charlotte, NC USA 28277

Our CFD Consulting Services

At FEAmax LLC, we specialize in providing top-tier Computational Fluid Dynamics (CFD) consulting services tailored to meet your specific needs. With over 20 years of experience in CFD simulation services, our team of experienced engineers leverages cutting-edge CFD techniques to deliver comprehensive solutions that optimize fluid flow, heat transfer, and related phenomena in your projects.

Whether you’re looking to improve the efficiency of HVAC systems, design more aerodynamic vehicles, or enhance industrial processes, our CFD consulting services are designed to provide accurate, reliable, and actionable insights. We use advanced simulation tools to model and analyze complex fluid interactions, ensuring that your designs perform optimally under real-world conditions.

Our Computational Fluid Dynamics consulting services cover a wide range of industries, including aerospace, automotive, manufacturing, and energy. By partnering with FEAmax LLC, you gain access to unparalleled expertise and innovative solutions that drive performance and efficiency.

Discover how our CFD consulting services, backed by over two decades of experience, can elevate your projects. Contact FEAmax LLC today to learn more about how our Computational Fluid Dynamics consulting can benefit your business. Let us help you achieve excellence in fluid dynamics and beyond.

What is CFD?

- Computational Fluid Dynamic (CFD) is a numerical simulation tool used to solve and analyze problems that involve fluid flows.

- CFD analysis helps engineers in understanding the problem appropriately and offers practical ideas for the best decision about the most flawless and productive design.

Our Mission:

- We offer cost-effective and professional Computational Fluid Dynamics (CFD) engineering consulting services online. Leveraging the power of the internet, we can seamlessly participate in your design projects as if we were in your office. Our expertise spans solving a wide range of mechanical and structural engineering analysis problems, ensuring comprehensive and efficient solutions for your engineering needs.

What we need to determine the quote and run CFD simulation:

- 3D CAD model, or 2D drawings with all dimension information.

- The detailed load condition.

- Material property for each component.

- What are your main concerns from the analysis.

What we provide on CFD project:

- A full standard CFD analysis report including results, conclusion, comments, suggestions, etc.

- The CFD results include: flow rate, pressure, velocity, volume fraction, temperature, cavitation, etc.

- Find out potential design issues and provide suggestions to optimize or improve the design.

- Colorful images and animation files.

- Q & A

Our Engineering Services

Area Of Expertise

Introduction of CFD simulation

Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) are numerical methods used to simulate physical phenomena, but they address different types of problems.

FEA is commonly used for structural analysis—determining the response of a structure under load. It can study deformation, stress distribution, and other attributes related to solid mechanics. It’s primarily used in fields like civil, mechanical, and aerospace engineering.

On the other hand, CFD is employed for analyzing fluid flow problems. This can involve simulating the flow of air over a plane wing or water through a pipe. CFD is widely used in aerospace, automotive, HVAC, and environmental engineering.

The mathematical approach differs too. FEA solves equations related to stress-strain or heat transfer, whereas CFD solves the Navier-Stokes equations that govern fluid flow.

FEA handles phenomena like plastic deformation and fractures in materials, while CFD manages turbulence, heat transfer, and chemical reactions in fluid flows.

For complex problems involving interaction between solid and fluid domains—known as Fluid-Structure Interaction (FSI)—both FEA and CFD may be used in a coupled manner. In summary, the choice between FEA and CFD depends on the specific problem and the physical phenomena to be simulated.

Computational Fluid Dynamics (CFD) is extensively used across numerous sectors due to its capacity to simulate fluid behavior. Some primary fields include:

Aerospace: CFD aids in aircraft and spacecraft design, optimizes shapes for drag reduction, and predicts aerodynamic performance.

Automotive: CFD improves vehicle aerodynamics, enhances fuel efficiency, and aids HVAC system design.

Energy: In power generation, CFD is crucial for designing and optimizing components like turbines, reactors, and heat exchangers.

Oil & Gas: CFD assists in pipeline design and prediction of oil and gas flow, ensuring safety and efficiency.

Maritime: CFD helps optimize hull shapes for minimal resistance, predict propulsion requirements, and analyze wave impact forces in ship design.

Environmental Engineering: CFD models pollutant dispersion, wind flow around buildings, and water treatment processes.

Biomedical: CFD is employed to analyze phenomena such as blood flow in arteries and drug delivery within the body.

Chemical Process Industry: CFD supports the design and optimization of chemical reactors and separation equipment.

HVAC: CFD contributes to enhancing airflow distribution, comfort, and energy efficiency in HVAC systems.

Weather Forecasting: CFD models aid in predicting weather patterns and severe weather events.

The applications of CFD continue to expand with advancements in computing power and simulation software.

While Computational Fluid Dynamics (CFD) is a unified field, it offers various types of analyses to address a wide array of fluid flow problems. These analyses can be broadly categorized as follows:

Steady State Analysis: This type of analysis assumes that all conditions are constant over time. It is used when the interest is in the final state of the system rather than its evolution.

Transient Analysis: In contrast to steady state, transient analysis deals with time-dependent flows. It captures how flow parameters evolve with time and is used for problems where the flow conditions change over time.

Compressible Flow Analysis: This analysis considers changes in fluid density significant, generally at high speeds (close to or above the speed of sound).

Incompressible Flow Analysis: Assumes that the fluid density remains constant, often applicable for low-speed flows.

Turbulent Flow Analysis: This type handles chaotic, irregular fluid flows characterized by rapid pressure and velocity changes.

Laminar Flow Analysis: This analysis is used for orderly and smooth fluid flows, where fluid particles move in parallel layers.

Multiphase Flow Analysis: It deals with flows involving more than one phase of matter (solid, liquid, gas), such as water droplets in air or bubbles in liquid.

Heat Transfer Analysis: This studies how heat energy is transferred in a fluid flow due to conduction, convection, and radiation.

Reactive Flow Analysis: This type of CFD analysis studies chemical reactions within the fluid flow.

The choice of analysis type depends on the specific problem or phenomenon that needs to be studied.

Obtaining accurate results from Computational Fluid Dynamics (CFD) simulations depends on a variety of factors. Here are some key consideration:

- Mesh Quality: The mesh discretizes the computational domain into small elements. A high-quality, well-resolved mesh, particularly in regions with high gradients (such as near walls or in regions of high turbulence), can improve accuracy.

- Physical Modeling: It’s crucial to choose the correct physical models for the problem at hand. This includes choosing the right turbulence model, heat transfer model, multiphase model, etc., based on the specifics of your scenario.

- Boundary Conditions: Proper specification of boundary conditions (inlet, outlet, wall conditions, etc.) is vital. Incorrect or unrealistic boundary conditions can lead to inaccurate results.

- Numerical Schemes: The numerical schemes used for time integration and spatial discretization can significantly impact solution accuracy. Higher-order schemes generally provide more accurate results but may be more computationally demanding.

- Convergence: Ensure the solution has adequately converged. Monitoring residuals can provide insights into whether the solution has reached a steady state (for steady state problems) or whether the transient solution has become stable (for unsteady problems).

- Validation: Whenever possible, validate your CFD results against experimental data or analytical solutions. This can give you confidence in the accuracy of your CFD simulations.

- Software Proficiency: Lastly, proficiency with the CFD software being used is crucial. Understanding the underlying methods, capabilities, and limitations of the software will help you make informed decisions throughout the simulation process.

- Here are ten widely used Computational Fluid Dynamics (CFD) software packages among engineers:

- ANSYS Fluent: Widely used for modeling fluid flows and heat transfer in complex geometries. It offers robust multiphase flow modeling capabilities.

- Star-CCM+: This Siemens product offers comprehensive simulation capabilities (CFD, finite element analysis, etc.). It’s known for its powerful meshing capabilities and user-friendly interface.

- OpenFOAM: An open-source CFD software that’s highly flexible and customizable. It is widely used in both academia and industry.

- COMSOL Multiphysics: Offers a wide range of physics simulations including CFD. It’s popular for its ability to solve multiphysics problems.

- Autodesk CFD: Known for its integration with Autodesk CAD software, it’s popular in the building and architecture industries for HVAC and external aerodynamics simulations.

- CFD++: Developed by Metacomp Technologies, it’s a versatile tool widely used in aerospace and automotive industries.

- CONVERGE CFD: Popular for its autonomous meshing capabilities, it’s extensively used in the automotive industry, particularly for internal combustion engine simulations.

- Altair AcuSolve: Part of Altair’s suite, known for its robust and scalable solver for complex fluid dynamics and multiphysics problems.

- NUMECA Fine/Marine: Specializes in marine and naval applications, known for its powerful wave modeling capabilities.

- SimScale: A cloud-based simulation platform that offers CFD, FEA, and thermal simulation capabilities.

Computational Fluid Dynamics (CFD) involves several methodologies to solve fluid dynamics problems. Here are the key steps typically involved:

- Problem Definition: The first step in solving a CFD problem is to clearly define the problem. This includes identifying the physical domain, the fluid properties, the boundary conditions, and any other pertinent features of the problem.

- Physical Modeling: Depending on the problem, appropriate physical models need to be chosen. These include turbulence models, heat transfer models, multiphase flow models, etc.

- Geometric Modeling: The geometry of the domain needs to be represented in a digital form. This could be done using CAD (Computer-Aided Design) tools.

- Grid Generation (Meshing): The geometric domain is divided into smaller subdomains or cells (a process called meshing). The quality of the mesh can significantly influence the accuracy and stability of the solution.

- Discretization: The governing equations are discretized, transforming them from continuous differential equations into a system of algebraic equations that can be solved numerically.

- Solver Selection and Solution of the Algebraic Equations: The algebraic equations are solved using suitable numerical methods (solvers). Depending on the complexity of the problem, this might be done using direct methods or iterative methods.

- Post-processing: After obtaining the solution, it needs to be analyzed and visualized. This could involve plotting velocity or pressure contours, streamlines, or other relevant quantities.

- Validation and Verification: The final solution should be checked for accuracy by comparing it with experimental data or analytical solutions, where available.

CFD Simulation Project Showcase

CFD Water Flow Analysis

We performed CFD steady and transient state fluid analysis on many water flow related projects. In the realm of water resources engineering, CFD Water Flow Analysis is instrumental in designing efficient hydraulic systems, optimizing water treatment processes, and mitigating flood risks. For instance, it can model and predict how water will flow around a dam, through a pipe, or around a water turbine. It can also help evaluate the impact of changes to riverine environments or predict sediment transport phenomena.

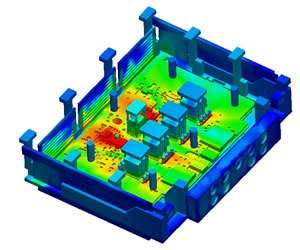

CFD Thermal Analysis

CFD Thermal Analysis models and analyzes how heat is transferred in a fluid, which could be a liquid or gas, and how it interacts with solid structures. It takes into consideration various thermal parameters such as temperature, heat flux, and conduction, convection, and radiation coefficients. By doing so, it can predict the thermal performance, heat distribution, and temperature gradients in a system or process. This analysis finds extensive use in various fields, including automotive, aerospace, electronics, and HVAC industries.

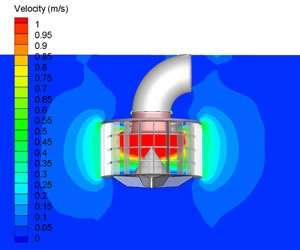

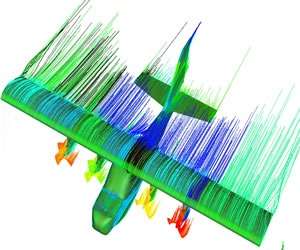

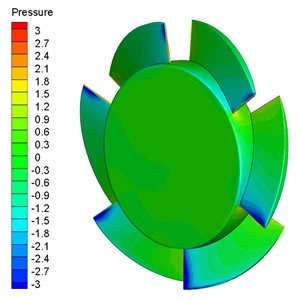

CFD Air/Gas flow Analysis

CFD Air/Gas Flow Analysis takes into account parameters like pressure, temperature, velocity, and density to generate a detailed depiction of gas flow dynamics. It is capable of predicting phenomena such as turbulence, vortex formation, compressible flow, and multi-phase interactions that can be challenging to measure or anticipate physically. This analysis can help design effective ventilation systems in buildings, optimize aerodynamics in automotive or aircraft design, assess pollutant dispersion in the atmosphere, and many more.

CFD Multiphase Flow Analysis

CFD Multiphase Flow Analysis provides a detailed representation of the flow dynamics by considering parameters such as pressure, velocity, temperature, and phase concentration. It can depict intricate phenomena like phase change, droplet formation and breakup, bubble rise, and particle sedimentation, which are often challenging to analyze experimentally. This method is indispensable in numerous industries, such as oil and gas, chemical, pharmaceutical, and environmental engineering. It can assist in optimizing oil recovery processes, improving chemical reactors, developing pharmaceutical products, etc.

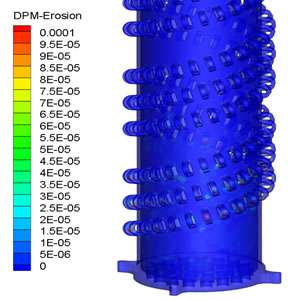

CFD Erosion Analysis

Computational Fluid Dynamics (CFD) Erosion Analysis is an advanced computational method used to predict and analyze erosion rates within different systems caused by the flow of fluids carrying abrasive particles. It simulates the movement and impact of particles, and their subsequent effects on the surfaces they interact with. CFD Erosion Analysis considers various parameters such as particle size, concentration, velocity, impact angle, and material properties to provide an in-depth understanding of erosion dynamics. It is capable of predicting phenomena such as abrasive wear, material degradation, and surface damage.

Fluid-solid Coupling Analysis

CFD Fluid-Solid Coupling Analysis takes into account a range of parameters like pressure, velocity, temperature, and material properties. It is capable of predicting intricate phenomena such as fluid-induced vibration, deformation, thermal expansion, and stress distribution, which can be challenging to analyze or measure physically. This technique finds extensive use across various industries such as aerospace, automotive, civil engineering, and biomedical fields. For instance, it can assist in designing efficient aircraft and vehicles, predicting the structural safety of dams or buildings subjected to fluid forces, or analyzing blood flow within human veins and arteries.