BLOG & Knowledge

We provide professional engineering design, analysis, manufacturing, and global sourcing services at a low cost and with a quick turnaround.

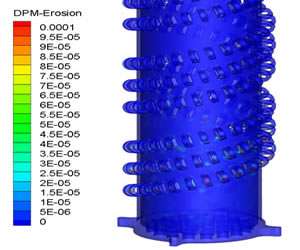

CFD Erosion Analysis on Oil-Gas Pipe

Perform CFD Erosion Analysis on Oil-Gas Pipes. Predict velocity, pressure, cavitation, erosion, etc. Find out potential issues and optimize the design...

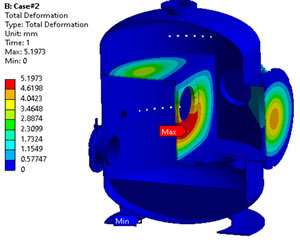

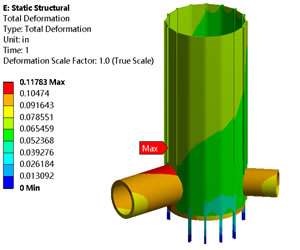

Read MoreFEA Stress Analysis on Pressure Vessel

Perform FEA structure stress analysis on pressure vessel model. Predict stress, deflection, safety factor, etc. and optimize the design...

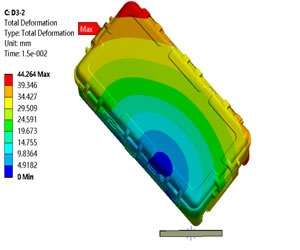

Read MoreFEA Dynamic Impact Analysis on Cooler

Perform FEA dynamic impact and drop test analysis on cooler assembly model. Predict stress, deflection, safety factor, etc. and optimize the design...

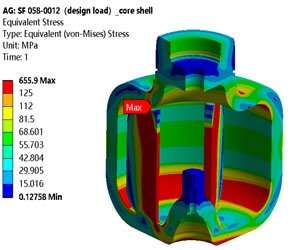

Read MoreFEA Structure Stress Analysis on Bladder Mold

Perform FEA structure stress analysis on pressure vessel - bladder mold model. Evaluate the stress per ASTM standard...

Read MoreStructure Stress Analysis on Tunnel

Perform FEA static structure stress analysis on underground concrete tunnel model. Predict stress, deflection, safety factor, etc. under soil and gravity loads...

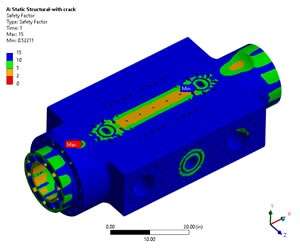

Read MoreCrack Propagation Analysis on Engine

Perform FEA fracture and crack propagation analysis on compressor cylinder. Predict stress, deflection, safety factor and evaluate crack on the part...

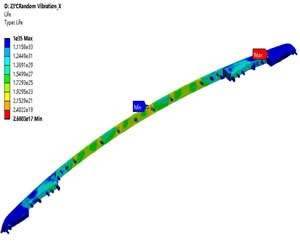

Read MoreVibration & Fatigue Analysis on Vehicle Lamp

Perform FEA vibration and fatigue stress analysis on vehicle rear fog lamp. Predict vibration response stress, fatigue life, etc...

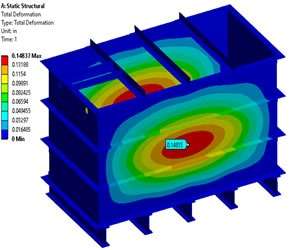

Read MoreFEA Hydrostatic Analysis on Water Tank

Perform FEA hydrostatic pressure stress analysis on water tank assembly. Compare and optimize the current design for better performance...

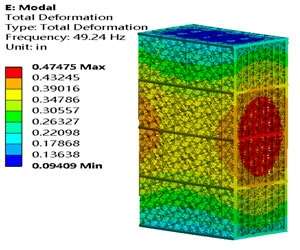

Read MoreFEA Vibration Analysis on Buried System

Perform FEA vibration stress analysis on Underground geocellular system. Predict the modal, response spectrum, stress, etc. in three directions...

Read More